Consider purchasing a new chair from Ikea. You provide the flat box house and open it up. But rather of grabbing a hex wrench and kissing your weekend goodbye, you pop a bottle of wine, sit again, and look at the chair grow from a flat piece of wood proper in entrance of your eyes.

This is the likelihood of what University of Stuttgart scientists are contacting HygroShape. It is flat-packed wood furniture that, over the class of about 8-12 several hours of sitting down in your residence, can grow to be a strong chair or chaise lounge. Whilst this is cutting-edge study, the 1st invest in-equipped items will hit this spring from a enterprise named Hylo Tech.

“Hylo Tech” is a little something of a nod at “high reduced tech,” which is how the aptly named researcher Dylan Wooden describes his team’s new engineering (Wood co-established Hylo Tech with Laura Kiesewetter). Today, most wooden home furnishings marketed by Ikea consists of obliterating a tree into sawdust, then applying glue to bind the wooden back together into many designs. Far more exciting, 3D-printed wood—which just debuted final year—works in largely the same way. An inkjet prints tiny bits of sawdust and binder into styles.

These types of wood composite products and solutions can be long lasting, but they also battle towards them selves. Trees are the natural way stuffed with fibers that make them strong. Sawdust breaks these wooden fibers down to generate a powder materials with no inherent mechanical strength. “With composites, you spend so much energy—literally energy, but also effort—to refine them and make them great,” states Wooden. “Then you set all this work to get them back again into new styles.”

HygroShaping will work completely differently, because it not only preserves the all-natural homes of wood, but it in fact relies upon on them to variety a piece of home furniture. Here’s how it is effective: The scientists get a tree. Slicing it into planks, they scan every piece, for both its grain and its h2o information. (This could seem like a lot of operate, but in simple fact, it is what most sawmills now do to quality trees.) What is novel is that the scientists have built software program that can analyze this wooden grain and humidity, and then have an understanding of how it will bend as it normally dries out.

“Wood is anisotropic. It has a coordinate program. To the lay person this is known as the grain. That’s the crucial,” says Wood. “You ordinarily have to be very thorough about this coordinate procedure and how you use it, but it can be pretty technically mapped out. Portion of the cleverness in what we do below is we kind of put it back again alongside one another in a a bit various way.”

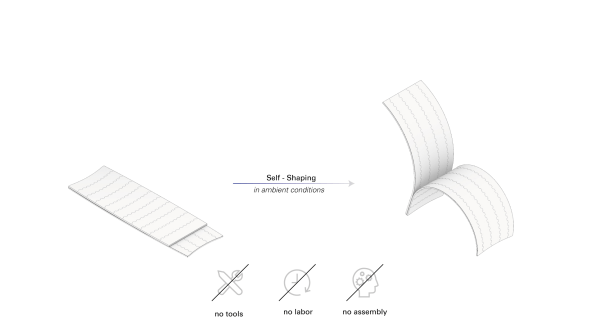

The scientists chop the tree into puzzle pieces. (The items resemble the foam-floor paneling of a house fitness center or baby participate in region.) Then they assemble just the suitable items together in a sandwich of flat boards, which will be packed into humidity-trapping packaging when still moist for delivery. Once unpacked, these boards dry and exert tension on a single yet another to generate a pretty individual condition: your new piece of furnishings.

“There’s a hidden code in the format of the boards,” claims Wooden. “And when you place them into your home, which is generally dry, they dry out and this physical shape emerges from this code.” Of training course, that code is not truly created by individuals. It is simply how these tiny items of wood favor to condition on their own. Making use of computation and clever style and design, individuals are exploiting the normal inclination of wooden.

Wood compares his team’s approach to the gracefully molded wood shell you see in the Eames Lounger, a hallmark of midcentury present day layout, and at the time, a breakthrough on wooden processing. To make these chairs to this working day, Herman Miller presses a thin sheet of wood into a mildew, just about like it’s plastic.

“We appreciate the Eames chair. We pretty much see this virtually as a reinvestigation of that spirit,” states Wood. “But what is stunning is that we can get the shape just from the pieces and the components. We never require the mildew, fundamentally.”

Are there any constraints to the HygroShape method? Most undoubtedly. The team nonetheless has incomplete facts they do not yet know how far they can push all styles of wood into which types of kinds. Yet another issue is that, due to the fact this is a all-natural shaping process—literally, the wood is shaped by its own drying—there’s some variation on how the precise identical chair design will truly render in wooden. The exact same chair will glimpse a very little little bit different every single time—and not just its grain, but its geometries. Wood says the group is at present attempting to dial in its computational technological know-how so that it can create home furnishings with the suitable degree of predictability, whilst leaving a bit of room for purely natural variation.

“We generally assumed we desired it to glance accurately like the image,” suggests Wooden. “But trialing with mates and colleagues, [we learned] there basically is a kind of price to the matters staying a little various, and expressing the variation they have in the wood.”