Inside a workshop in the vicinity of Boston, a 6-foot-extended 3D printer is churning out furnishings that appears to be indistinguishable from wood, designed layer by layer from sawdust that usually would have been squandered.

“We’re avoiding trees from staying minimize down,” says Andy Jeffrey, CEO of Forust, the startup that developed the printer, which is the winner of the artwork and structure category of Rapid Company’s 2022 Entire world Shifting Tips Awards. In the U.S. alone, he suggests, practically 100 million tons of sawdust is generated each and every calendar year, the equal of 30 to 40 million trees. Significantly of that sawdust is either incinerated or sent to landfills.

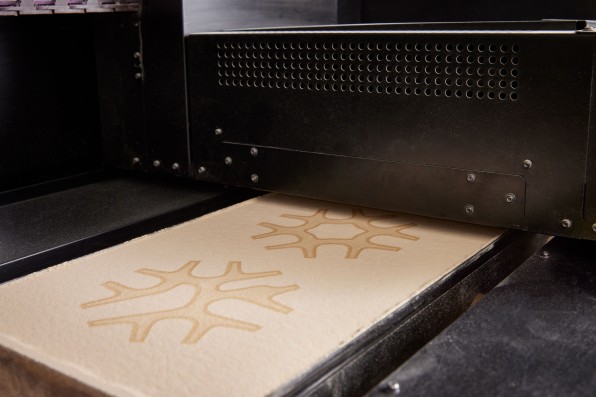

The large 3D printer spreads out skinny levels of sawdust, and each and every layer is topped with an environmentally friendly binder that contains lignin, an adhesive substance that arrives from trees and naturally will help hold with each other wooden. Sawdust from any form of tree can be remodeled by the printer into wooden that seems like a distinct species.

By varying the density of the sawdust—a minor like the way a regular printer can print in grayscale by varying the density of black ink—the printer can also recreate wood grain like oak or teak or even endangered species like rosewood. And due to the fact it is printed in levels, the grain goes all the way as a result of each individual item, compared with particle board.

“This is not just an impression which is applied to the floor of the wood—it is a assets that goes absolutely by way of the wood,” says Jeffrey. “Every layer has that grain . . . you can refinish it, sand it down, put another lacquer onto the wooden and you will not get rid of the grain influence. It is intrinsic to the complete piece.”

Since the approach can sculpt an object as it prints, it’s probable to design and style items that are more intricate than could very easily be created with regular carving. The firm is now making a wide range of products and solutions, from sculptural bowls to car or truck components, and redesigning other folks, like golfing tees with an less difficult-to-use shape that could not be built by way of regular production.

Given that sawdust is broadly out there all over the planet—along with other wooden squander like supplies from development sites—the printers could be employed everywhere and help eradicate provide chain challenges that exist for wood now. “It does not make sense to really ship sawdust all-around the environment,” he claims.”The form of manufacturing we envisage is a additional distributed manufacturing product wherever you are not reliant on significant provide chains to ship sawdust to a big central area, and then ship merchandise all around the environment.”